Sugar & Distillery Processing Additives

Sugar and distillery processing additives are crucial in optimizing the production and quality of alcoholic beverages. In sugar processing, additives like phosphoric acid and lime are used to clarify juice and enhance crystallization. These help in efficiently extracting and purifying sugar from sugarcane or beets. In distillery processes, additives such as enzymes, yeast nutrients, and fining agents improve fermentation efficiency, enhance flavor profiles, and ensure the clarity and stability of the final product. These additives play a key role in achieving the desired consistency, flavor, and purity in both sugar and alcohol production.

Antifoaming Agent

STI 150 Silicone Defoamer

- STI 150 Silicone antifoaming liquid is a white emulsion manufactured from Natural Silicone oil and unsaturated fatty acids.

- It’s have lower surface tension than sugar solution

- It’s never leave any stains or color in sugar.

- Disperse readily & rapidly.

- It’s chemically inert, nighther involved in sugar processing nor side reaction.

Biocide Mill Sanitation

i) STI 700 Quarternary Ammonium compound

STI 700 Quarternary Ammonium Compound based broad spectrum biocide. It will minimize Inversion losses due to gram positive & gram negative

bacteria and other microorganisms.

ii) STI 705 Dithio Carbamate Base

STI705 Dithio Carbamate based broad spectrum biocide. Its controls the Leuconostoc bacteria and other microorganisms.

Colour Precipitans

Specialty polymer to improve sugar colour during clarification process.

We are supplying 3 types of colour precipitants for sugar mills.

- STI 701 Juice colour precipitant

- STI 702 Syrup colour precipitant

- STI 703 Melt colour precipitant

Banefits

Improves the clarification efficiency, Produces a superior white sugar, Removal of suspended solids and colloidal particles in sugar juice and syrup.

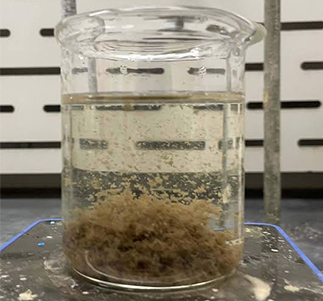

Flocculants

We are supplying3 types of Flocculants used in the sugar process

STI 707 Juice Flocculant

STI 707 Juice Flocculant clarifies sugarcane juice by removing colloidal impurities and insoluble suspended solidws.

STI 708 Syrup Flocculant

STI 708 Syrup flocculant dosed in the Phosphated & aerated sugar syrup before entry in to the clarifier. It is cost effective process and sugar yield is increases.

STI 709 Melt Flocculant

STI 709 Melt flocculants are used to clarify melt liquor before it enters into the clarifier. Flocculants are added to the melt liquor to help remove impurities from the juice.

Oil Base Distillery Defoamer

Oil based Distillery Defoamer

STI 250 Oil based Distillery Defoamer is manufactured from natural Castor oil

by adding suitable solvents and Alkalinity builders.

Banefits

- It’s a water soluble amber coloured viscous oil.

- It controls the foam generation in the Distillery fermentation process.

- It never controls or kills the fermentation process microbes & enzymes.

Evaporator Antiscalant

Evaporator Antiscalant is a polymer based powerful product. It Control the deposition of scale forming salts like Calcium carbonate and Sulphates and Silica.

Enzymes

Enzymes are biological catalysts that speed up chemical reactions in sugar processing, helping to extract and purify sugar more effectively.

Seed Slurry

Seed slurry is used in the sugar process to get free flow and uniform size crystals. Seed slurry reduces the viscosity of Massecuite. It improves the circulation of the Massecuite within the pan. It gives better purging of low grade massecuite at the centrifugal.

Viscosity Reducer

STI 805 Viscosity Reducer is poly acrylate based Product to reduce the viscosity of sugar syrup during pan and Massecuite. It improves circulation, shortens boiling time, improves sugar recovery, helps purging, Reduces ash content, lubricates crystals effectively.